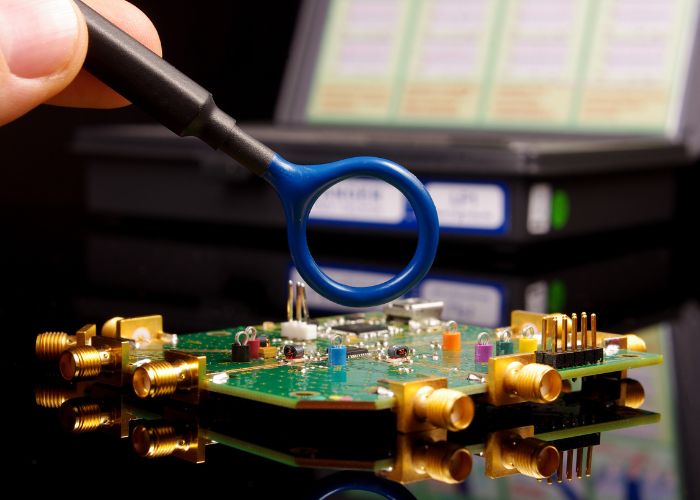

EMC is a critical factor in the success or failure of a PCB design. If you’re a PCB designer unfamiliar with EMC, we’ll explain what you need to know about EMC and how to make your PCB design more EMC-friendly.

What Is EMC?

First, what does EMC mean, and why is it important for PCB designers? Electromagnetic compatibility (EMC) refers to the interaction of electronic equipment and devices with the electromagnetic environment and other equipment.

All electronic devices emit small electromagnetic fields, which, when near one another, can interfere with the electrical flow of other devices and cause interference. EMC means that the equipment or device is compatible with the electromagnetic environment and does not emit excessive electromagnetic energy that causes interference. Naturally, PCBs are sensitive electronic equipment, so it’s crucial that the design feature EMC.

What Is EMI Shielding?

One way to reduce the effect of the electromagnetic interference (EMI) of the electromagnetic fields in PCBs and electronic equipment is with EMI shielding. EMI shields can protect your PCB from EMI by preventing outside EMI from interfering with the PCB and reducing the PCB’s electromagnetic emission with certain techniques and materials.

EMI shielding is utilized in practically every industry with electronic devices and equipment, which is nearly every modern industry, including:

• Consumer electronics

• Health care

• Telecommunications

• Aerospace

• Automotive

• And more

How Can I Make My PCB Design More EMC Friendly?

Clearly, EMC is an important factor in PCB design, but what can designers do to make their PCBs more EMC-friendly besides EMI shielding?

Ground Planes

Ground planes are integral to EMC as it reduces electromagnetic emission and interference. Some strategies that PCB designers can employ include using the entire ground plane and avoiding long return paths.

Connecting the device grounds directly to the ground plane will also help reduce ground loops and offer better EMC performance.

Avoid Right Angles

The trace spacing and layout are also critical aspects PCB designers need to know about for their PCB’s EMC. Avoid right angles when designing the trace layout, as they increase the capacitance. Instead, make corners more EMC friendly by replacing them with 45-degree turns.

We hope our explainer has helped you learn more about the relationship between PCB design and EMC. Before you begin your next PCB design, make sure you understand the basics of EMC and how it can affect your PCB.