- Creating a new model requires over six million litres of paint, 1,200,000 kilometres of testing or 55,000 simulations

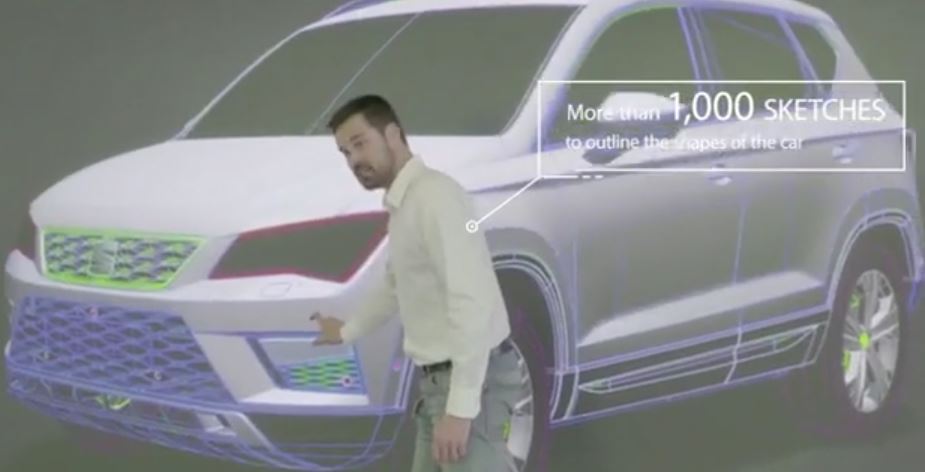

- More than 1,000 sketches are made before settling on the final design of a vehicle

- 80% of the approximately 400,000 cars manufactured every year are exported to a total of 75 countries

Martorell, 03/01/2017. – It covers an area of more than 2.8 million square metres, equivalent to 400 football pitches, and produces around 400,000 cars annually. These figures correspond to the SEAT Martorell factory. But what are the specific numbers involved in making a car?

Four years elapse from the initial concept until an actual car is made, but every new model always begins exactly the same way – with pencil and paper. Until settling on the final design over 1,000 sketches are drawn. In the SEAT Technical Centre, drawings take their 3D appearance in the form of clay models, which require more than 5,000 kilos to shape.

It takes three years of intense work to create a new colour, and in the Martorell plant a total of 6.4 million litres of paint are used every year, enough to paint the Eiffel Tower 100 times. The Technical Centre employs more than 900 engineers who develop the models and perform over 55,000 simulations per year to guarantee safety and comfort inside the vehicles. Roughly 400 smell and touch tests are carried out annually on all the parts and materials inside the passenger compartment to ensure a pleasant experience for future customers.

Before a new model goes on sale, around 50 engineers test the prototypes by pushing their limits over 1,200,000 kilometres of Summer and Winter driving tests every year in deserts and on icy roads.

In the workshops, over 2,000 robots are busy assembling the more than 3,000 parts that make up a car. At the end of the process, 80% of the production will be exported to the 75 countries where SEAT operates.